Lens Spotlight

HLB M Plan Apo 2x

The HLB M Plan Apo 2x is a microscope objective designed for metallurgical applications. This test aims to evaluate how well it performs in focus stacking setups without the use of a professional microscope.

The Objective

The HLB M Plan Apo 2x is an objective specifically developed for metallurgical analysis. It belongs to a series of objectives with various magnification levels, all of which share the feature of parfocality—meaning each objective in the series has the same total length, including housing and working distance. The housing diameter is also largely consistent, which poses a particular design challenge at such low magnification levels, especially around the front lens.

The advantage of this parfocal design becomes especially apparent in specialized microscopes, where the camera extension is mechanically calibrated to match the series—often in combination with a fixed tube lens. However, this construction is also beneficial in practical focus stacking setups, as it allows for easy lens swapping without the need for additional adjustment.

A long working distance is essential in metallography—not least because illumination often needs to come from the side. This sets industrial objectives apart from most traditional microscope lenses, which are designed for laboratory use in biology or medicine. In those fields, transmitted light is typically used, making a long working distance not only unnecessary but sometimes even problematic.

In contrast, the HLB M Plan Apo 2x—with its extended working distance—offers ideal conditions for use with a full-frame camera and tube lens in a stacking setup. The generous space between the lens and subject greatly simplifies lighting, as the object can be illuminated from almost any angle—an obvious advantage when capturing the fine details of structured surfaces with photographic precision.

The HLB M Planapo 2x is part of a parfocal objective series with an identical housing diameter.

The Manufacturer

The HLB M Plan Apo 2x is backed by the Japanese company Shibuya Optical, a manufacturer with a broad portfolio of precision optical instruments. The company produces lenses for a wide range of specialized fields, including custom microscopes and compatible accessories. In Europe, HLB objectives are distributed by Stonemaster (www.stonemaster-onlineshop.de).

The HLB series was most likely modeled on the well-known Mitutoyo line, which set benchmarks with its parfocality, long working distance, and outstanding image quality—though in a significantly higher price range. HLB has positioned itself as a more affordable alternative in this market and now offers optically convincing lenses that, in many respects, can stand up to the original.

Alongside HLB, numerous Mitutoyo clones from China are also available. These often look deceptively similar to the original but are offered at substantially lower prices. However, this external resemblance should not be mistaken for optical equivalence—because in optical systems, it’s not the housing that matters, but the precision inside.

The HLB M Plan Apo 2x featured here seemed especially worth testing because its counterpart from the Mitutoyo series ("M Plan Apo 2x") is considered problematic in practice: in a typical focus stacking setup using a 200 mm tube lens, it exhibits significant weaknesses and is only usable to a limited extent. The core question of this test, therefore, was whether the HLB objective delivers better optical performance in this regard.

This objective was kindly provided for testing by Rainer Ernst (Stonemaster).

Technical Specifications

Magnification: 2x

Numerical Aperture: 0.055

Infinity-Corrected Optics (requires tube lens)

Compatible Tube Lens Focal Length: 200 mm

Thread Diameter and Pitch: M26 x 0.706

Weight: 210 g

Housing Length: 60.6 mm

Housing Diameter: 34 mm

Parfocal Distance (housing length plus working distance): 95 mm

Focal Length: 100 mm

Working Distance: 34.4 mm

Resolution: 5.0 µm

Depth of Field: 90.9 µm

Imaging Performance – 208 mm Tube Lens

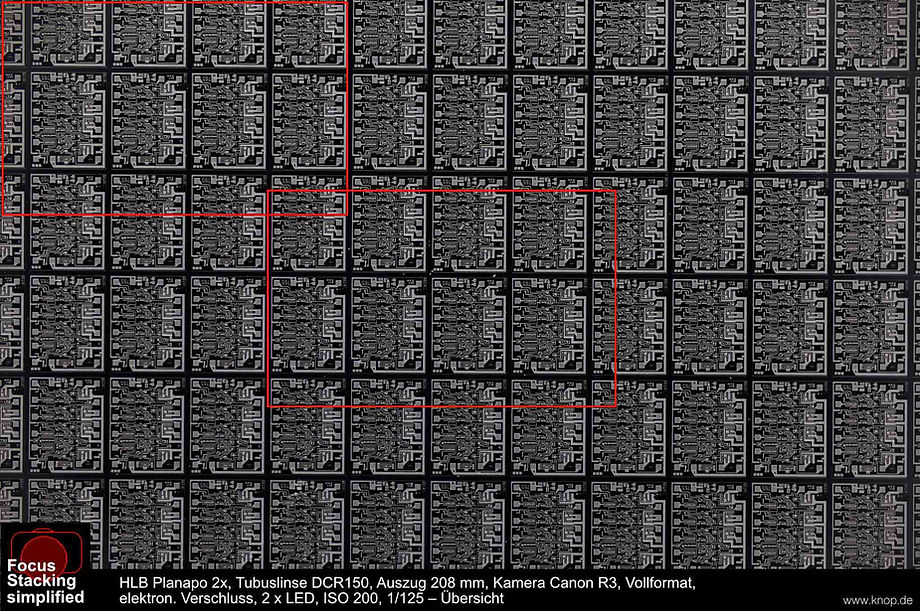

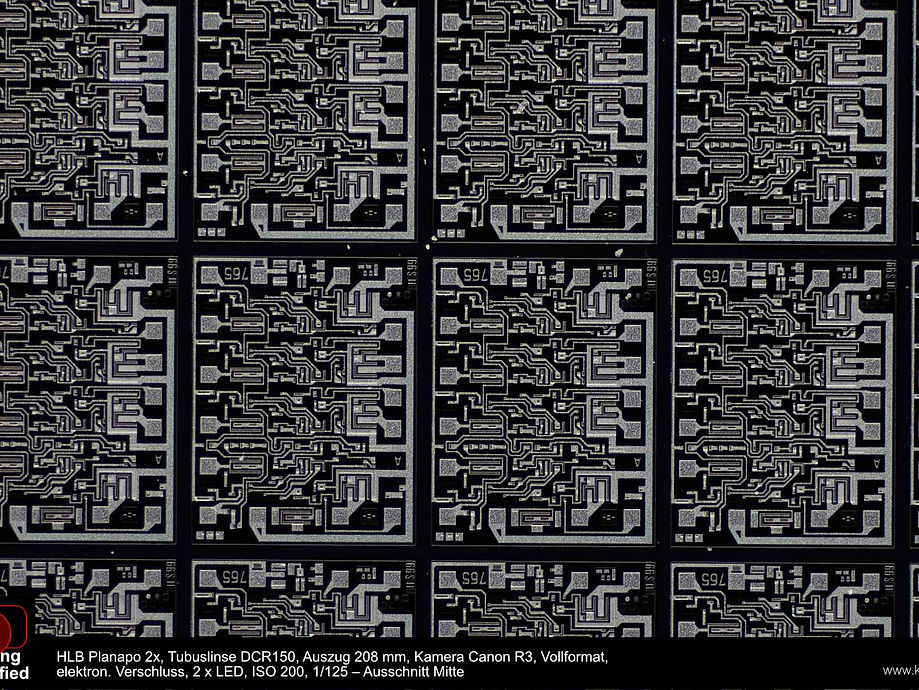

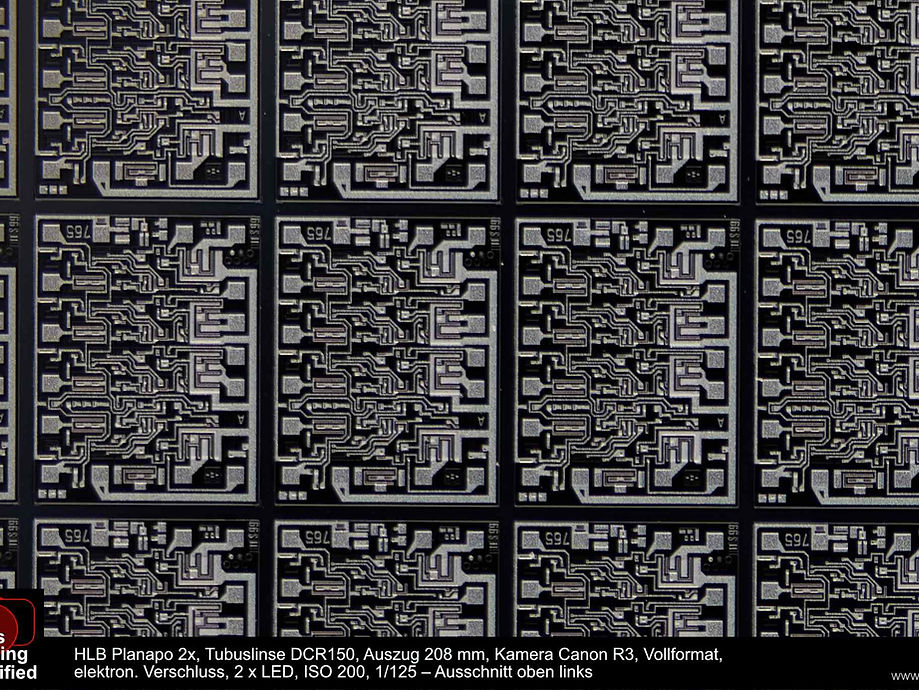

The following test images illustrate the imaging performance of the objective. The first shows an overview shot (full-frame sensor) taken with the Raynox DCR 150 as the tube lens, resulting in an approximate nominal magnification of 2x. The two subsequent images each display an enlarged crop.

Test image at nominal magnification (DCR 150), with frame markers indicating the areas shown in the following cropped enlargements — the initial overall impression is quite good; no visible darkening at the edges or corners, only slight pincushion distortion. However, image sharpness cannot yet be fully assessed at this stage.

The central cropped enlargement reveals poor detail sharpness, clearly visible in the small square structures.

The cropped enlargement of the edge/corner area shows that the already limited sharpness performance drops off toward the corner (in this case, the upper left). While the apochromatic correction effectively prevents noticeable color fringing (chromatic aberrations) even in this zone, the increasing blurriness extends across such a wide band that it would not be fully eliminated even when using a smaller sensor (APS-C, MFT).

This test image and its cropped enlargements show the HLB M Plan Apo 2x in use on a full-frame camera with a 208 mm tube lens—almost the configuration for which this objective was designed. With a numerical aperture of 0.055, it belongs to the low-resolution class of metallurgical objectives, optimized for low magnification at a long working distance. This image is insightful in that it clearly illustrates both the potential and the system-imposed limitations of optical performance in this category.

Center

In the center, the HLB M Plan Apo 2x delivers a relatively clean, well-balanced rendering of the test subject (silicon wafer). Main structures are clearly visible, and lines appear neatly separated, though without fine edge definition. Contrast is solid—not harsh, but sufficient to distinguish relevant structural elements. Fine details are not rendered with the sharpness seen in higher-resolution objectives, but this performance is fully in line with expectations for a 2x system with a 0.055 NA. No color fringing or notable spherical aberrations are present, indicating good axial correction. The central zone is thus well suited for structured objects of moderate density, such as electronic components, coins, or embossed surfaces.

Extended Center

In the extended center area, sharpness decreases slightly but evenly. Lines begin to appear a bit softer, especially in regions with high information density. Microcontrast noticeably fades—fine gradations tend to blur. Nevertheless, the overall image remains stable, with no sudden drops in sharpness or asymmetric errors. Field flatness is respectable, indicating a sound optical design—not something to be taken for granted at this magnification and sensor size.

Edge Zone

At the outer edge, the drop in image quality becomes apparent. Structures lose definition, darker areas appear slightly washed out, and fine lines begin to merge. Still, the image remains recognizable and geometrically accurate all the way to the corners, without distortion or skewed projection. It’s noteworthy that despite the lens's nominal image circle limitations, the full-frame sensor area is still covered quite evenly—though the corner data is limited in analytical usefulness.

Overall Impression

In its specified configuration, the HLB Plan Apo 2x delivers a well-balanced optical performance appropriate for its intended use. Center sharpness is good, contrast remains stable, and field correction is achieved without conspicuous flaws. In the extended image zone, the typical sharpness decline caused by limited numerical aperture becomes more evident, especially toward the edges—yet without introducing geometric artifacts.

For large-scale subjects with moderate structural detail—where lighting control, working distance, and repeatability are more critical than maximum resolution—this objective proves to be a capable tool. Especially in full-frame focus stacking applications, it can produce very even and clean results under controlled lighting—a practical compromise between working distance, compatibility, and imaging performance.

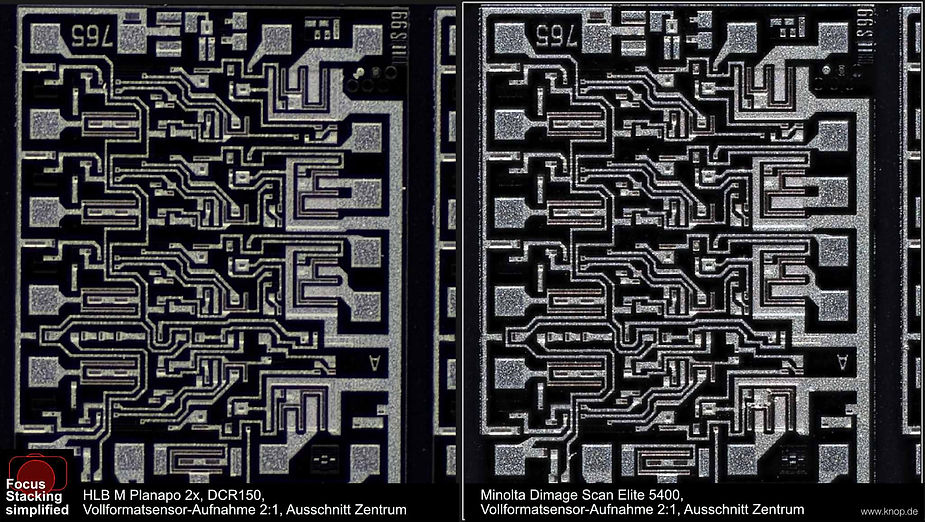

Comparison HLB M Plan Apo 2x – Minolta Dimage Scan Elite 5400

The direct comparison with the Minolta Dimage Scan Elite 5400 shows that the HLB M Plan Apo 2x cannot compete with this extremely high-quality and exceptionally sharp imaging lens in any category—in fact, it is vastly inferior. The fact that the color temperature drifted into lower Kelvin ranges was the least of the problems. While the images shown here were indeed upscaled significantly, this was done equally for both. Whereas the Minolta clearly separated even the finest particles—as clearly seen in the small square structures—the HLB only produced blurry light-dark transitions without any sharply defined contours, despite the fact that its image section, like the Minolta's, was taken from the center of the frame, where every lens is expected to perform at its absolute best.

The direct comparison between the tested HLB M Plan Apo 2x and the gold standard—the Minolta film scanner lens Minolta Dimage Scan Elite 5400—provides valuable insight into the sharpness performance of the test candidate.

Sharpness and Line Resolution

The Minolta lens shows a surprisingly high resolving power at the center. The circuit traces are clearly separated, with well-defined edges and consistently high microcontrast. Fine structures such as small angles, curves, and narrow gaps in the circuitry appear differentiated and rich in detail. In comparison, the image produced by the HLB 2x appears overall softer—while the lines remain distinguishable throughout, they are slightly widened in some areas, and contrast in fine sections seems somewhat flattened. In this regard, the Minolta lens clearly extracts more from the sensor—despite originally being designed as a dedicated line-optic system for film strips.

Tonal Depth and Contrast

The Minolta lens also impresses in terms of grayscale rendering. The fine tonal gradations in both highlights and shadows appear smooth and yet well-differentiated—bright areas hardly show any blooming, and dark regions retain detail. The HLB, by contrast, delivers a more “technical” image: tonal gradations are present but less finely modulated. Especially in darker zones, there is a noticeable loss of contrast, which gives the image a slightly duller appearance.

Image Character and Sharpness Profile

The rendering of the Minolta lens overall appears more precise, crisper, and more finely tuned, while the HLB produces a somewhat flatter, more robust image—well suited for quick overviews and technical assessments, but lacking the microscopically “refined touch” of the Minolta. Interestingly, the film scanner lens’s output resembles that of a highly corrected macro lens, whereas the HLB remains true to its metallography roots—with a long working distance and the typical, more moderate resolution paired with a broad correction zone.

Overall Impression

In a direct comparison of both lenses at the same magnification on a full-frame sensor, the Minolta lens proves to be the sharper and more nuanced system. It delivers a clearer, more contrast-rich image in the center, with better-resolved fine structures and higher microcontrast—an impressive feat for a lens never originally intended for imaging three-dimensional objects. The HLB M Plan Apo 2x remains a solidly corrected industrial lens with uniform performance, broad compatibility, and generous working distance—but in terms of image sharpness and fine contrast, it is visibly outperformed by the Minolta in this setup.

For those seeking maximum detail resolution at a 2:1 magnification on full-frame sensors, the Minolta lens presents a highly compelling alternative—provided it can be reliably adapted mechanically. The HLB, on the other hand, remains a stable, industry-oriented solution for repeatable setups where working distance, modularity, and robust optical tolerances take precedence.

Resolution Test

The Zeiss Resolution Test 300 allows the resolution of a microscope objective to be read as a numerical value. While this reading is somewhat open to interpretation and not entirely precise (see details here), it does provide a general impression of the objective’s fine rendering and detail reproduction.

The resolution value, shown here in the two upper fields, was measured at the center of the lens at 160 line pairs per millimeter (lp/mm).

Conclusion

The HLB M Plan Apo 2x shows a mixed performance in practical use on a full-frame sensor with a 200 mm tube lens. At the image center, the lens delivers an acceptable—though soft—rendering with discernible detail structure. However, microcontrast is low, and fine structures are not reproduced with the precision that modern sensors are technically capable of capturing. Sharpness drops noticeably in the extended zone, and clear optical limitations appear in the peripheral areas—such as increasing blur, falling contrast, and chromatic aberrations.

These performance losses cannot be significantly compensated by changes in configuration (e.g., adjusting the camera extension or using alternative tube lenses). Neither shortening the extension nor reducing the tube lens focal length led to improvements—in fact, these setups resulted in heavy vignetting or visible image field reduction, further limiting the lens’s suitability for full-frame imaging.

The causes likely lie in the physical constraints of the series: the requirement for parfocality combined with a long working distance and a constant housing diameter forces optical compromises, which have particularly negative effects at lower magnification ratios. Here, the front optics appear to be reaching design limits, as the lens surface is pushed into optically problematic edge zones. A front element with a larger diameter might have improved performance—either by enabling a higher numerical aperture at the same working distance or by allowing greater use of the better-corrected central zones of the lens without having to rely on the more error-prone outer regions. However, the design constraint of a uniformly slim housing within the parfocal series apparently did not allow for this option.

Despite its solid build quality and a design generally suitable for reflected-light applications, the HLB 2x is not ideal in its current form for high-resolution focus stacking with modern full-frame sensors. For technical or documentary purposes where moderate detail reproduction is sufficient and the image edges are not critical, the lens may still be usable in specialized scenarios.

However, those who require consistently high imaging performance all the way to the corners—particularly for demanding macro photography or reproducible stacking series—will be better served with other systems. In this magnification range, high-quality film scanner lenses are recommended, offering significantly better resolution and optical correction—even with much lower numerical apertures.

Advantages

Compared to high-end lenses: lower purchase price, extremely long working distance allowing optimal lighting, and parfocality within the lens series, enabling easy lens changes.

Disadvantages

Testbild mit DCR 250: Im Zentrum ist die Bildschärfe bei dieser Kombination nur moderat und deutlich geringer als bei der Nominalvergrößerung, und außerhalb des Bildzentrums lässt sie gewaltig nach. Hier zeigt sich auch eine leichte kissenförmige Verzerrung. Die Abdunklung des Rand- und Eckenbereichs ist deutlicher als bei Verwendung der DCR 150.

Das Bildzentrum hat noch gewisse Schärfe, aber feinste Details werden in Kombination mit der DCR 250 nicht mehr wiedergegeben.

Die Randzone weist starke kissenförmige Verzerrung und intolerable Unschärfe auf, die zur Ecke hin extrem wird (hier links oben). Im Vollformat ist diese Kombination aus Objektiv und Tubuslinse schlicht unbrauchbar.

Der direkte Vergleich mit dem Canon-Lupenobjektiv MP-E 65 mm bei Stellung 3,5x zeigt, dass das HLB Planapo 3,5x diesem sehr scharf abbildenden Makrospezialisten deutlich unterlegen ist. Das Canon bringt mehr Schärfe (Bild oben rechts), und der Schärfeabfall zum Bildrand und vor allem zu den Ecken hin ist beim Canon deutlich schwächer als beim HLB. Allerdings muss hier auch berücksichtigt werden, dass das HLB Planapo 3,5x neu weniger als die Hälfte dessen kostet, was für ein Canon MP-E 65 mm zu veranschlagen ist.

Vergleich HLB M Plan 3,5x – Canon MP-E 65 mm

HLB Planapo 3,5x (links) im Vergleich mit dem Canon MP-E 65 mm bei Stellung 3,5 (rechts), oben jeweils das rechte obere Viertel des Originalbilds, aufgenommen mit Vollformatsensor (Focus Stack), unten jeweils ein Sechzehntel des Originalbilds, entsprechend hochskaliert.

Fazit